HDA Flowsheet Simulation and Optimization

HDA Flowsheet Simulation and Optimization

Author: Jaffer Ghouse

Maintainer: Tanner Polley

Updated: 2025-11-19

Learning outcomes

Construct a steady-state flowsheet using the IDAES unit model library

Connecting unit models in a flowsheet using Arcs

Using the SequentialDecomposition tool to initialize a flowsheet with recycle

Formulate and solve an optimization problem

The general workflow of setting up an IDAES flowsheet is the following:

1 Importing Modules

2 Building a Model

3 Scaling the Model

4 Specifying the Model

5 Initializing the Model

6 Solving the Model

7 Analyzing and Visualizing the Results

8 Optimizing the Model

We will complete each of these steps as well as demonstrate analyses on this model through some examples and exercises.

Problem Statement

Hydrodealkylation is a chemical reaction that often involves reacting

an aromatic hydrocarbon in the presence of hydrogen gas to form a

simpler aromatic hydrocarbon devoid of functional groups. In this

example, toluene will be reacted with hydrogen gas at high temperatures

to form benzene via the following reaction:

C6H5CH3 + H2 → C6H6 + CH4

This reaction is often accompanied by an equilibrium side reaction

which forms diphenyl, which we will neglect for this example.

This example is based on the 1967 AIChE Student Contest problem as

present by Douglas, J.M., Chemical Design of Chemical Processes, 1988,

McGraw-Hill.

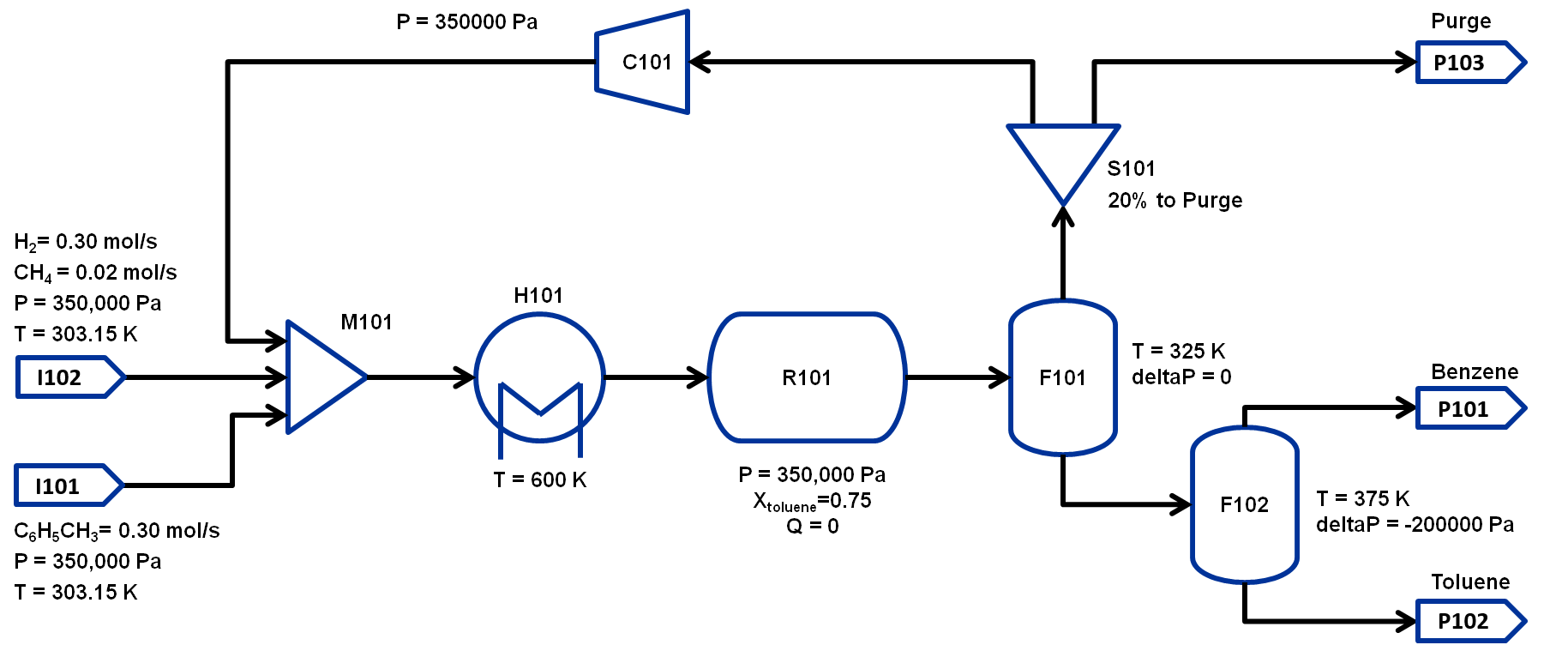

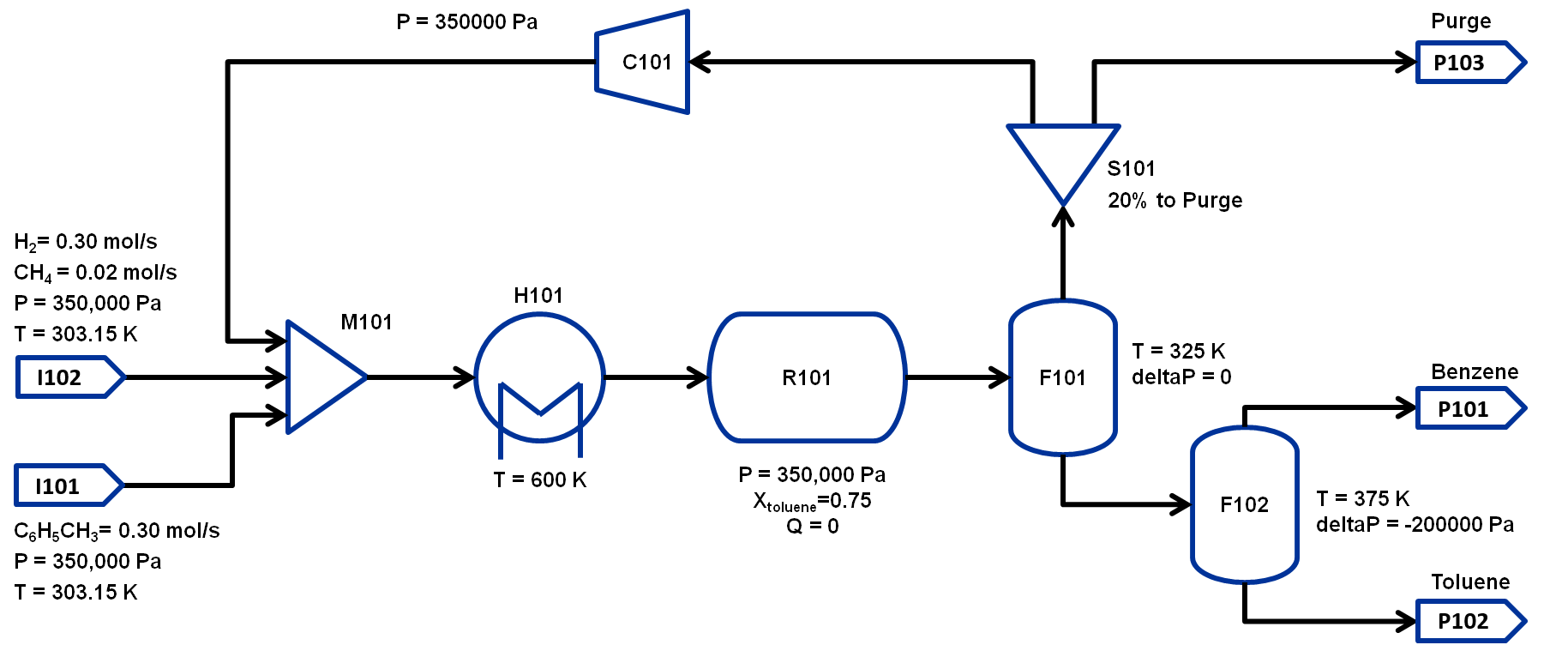

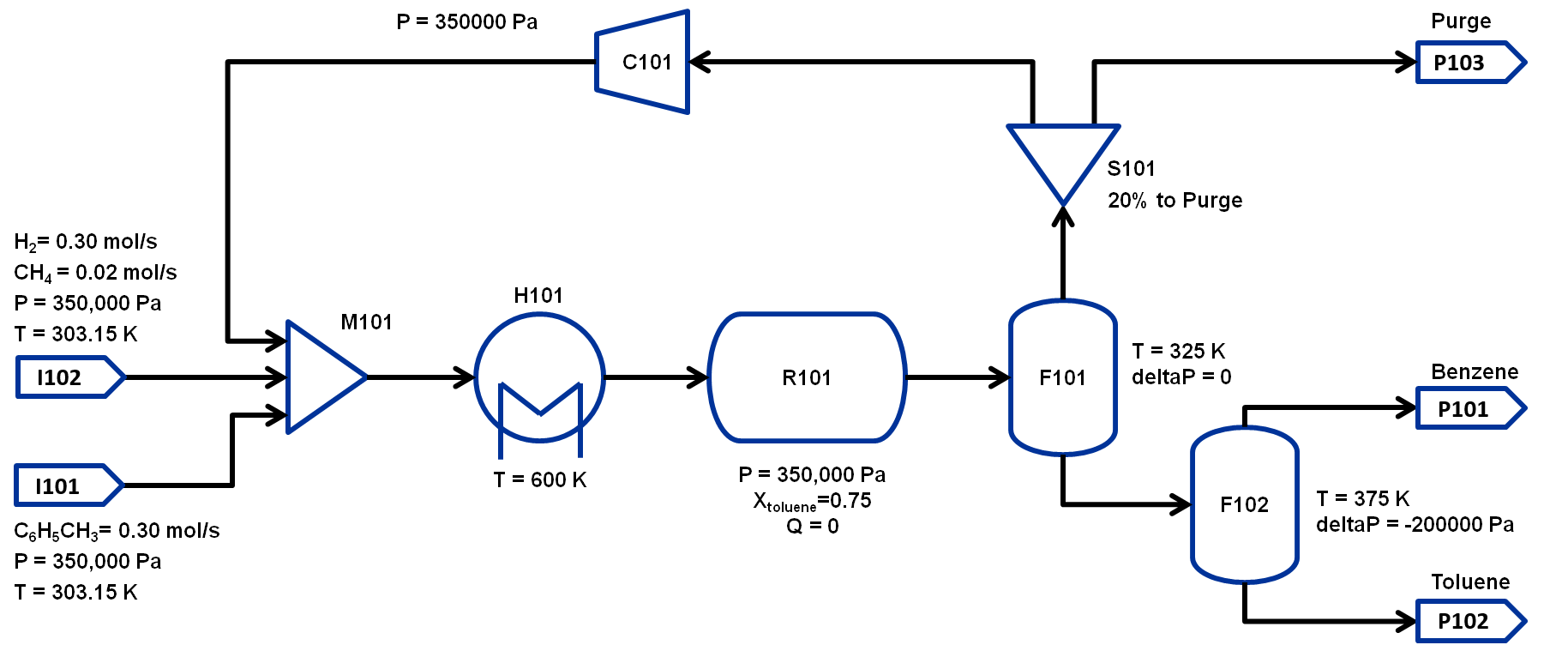

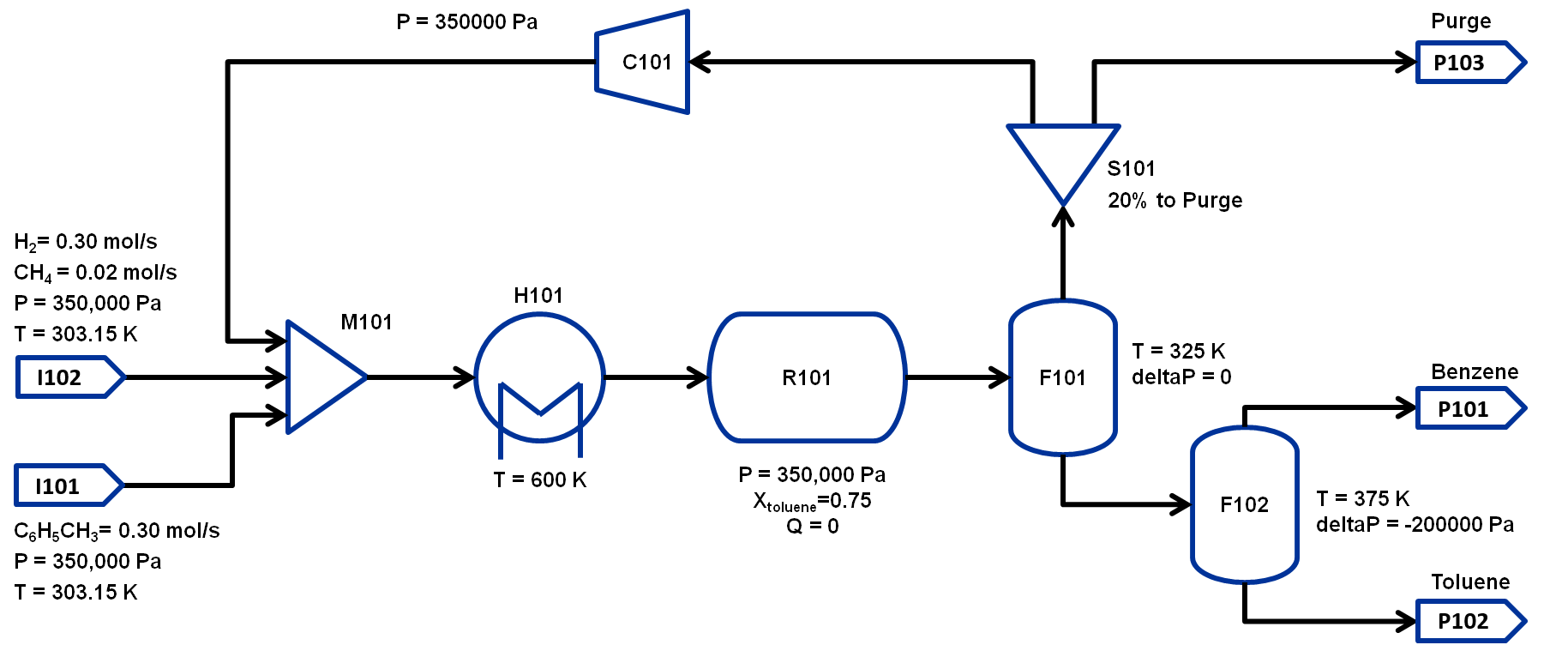

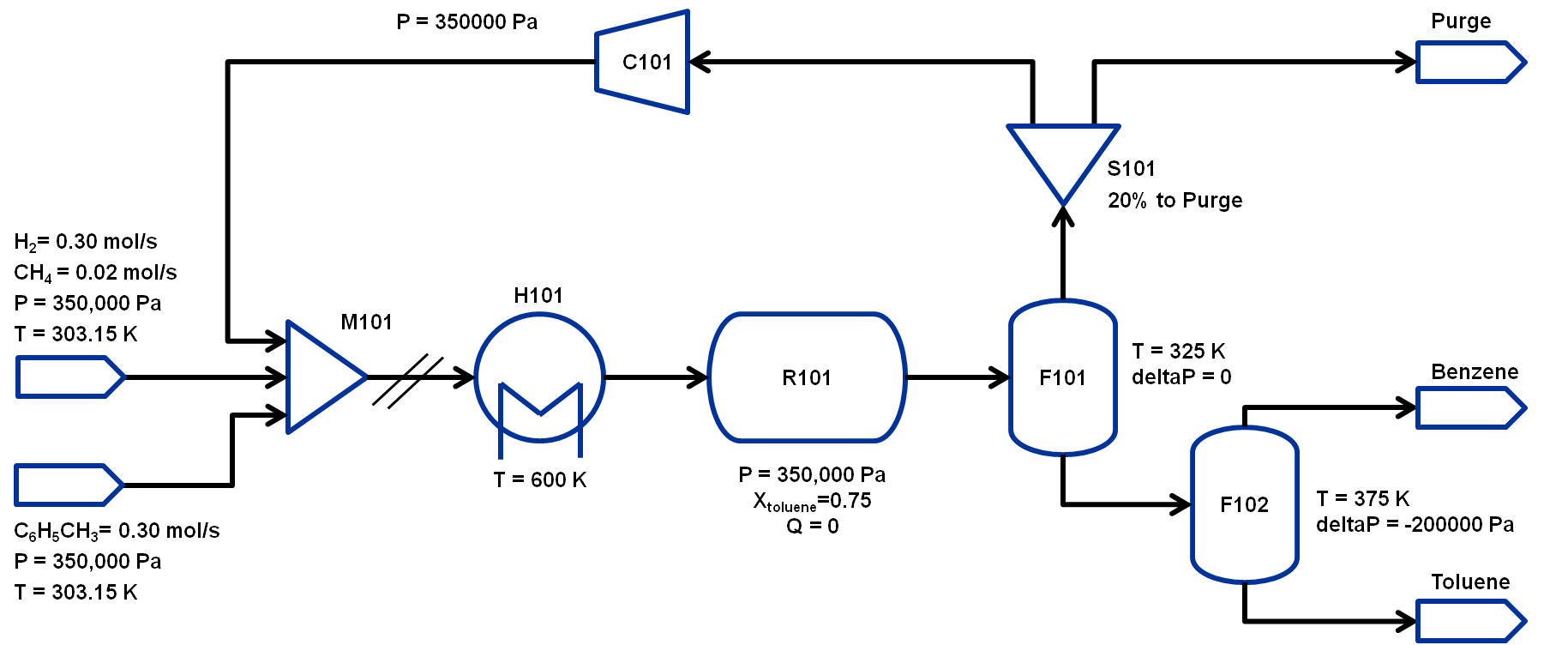

The flowsheet that we will be using for this module is shown below with the stream conditions. We will be processing toluene and hydrogen to produce at least 370 TPY of benzene. As shown in the flowsheet, there are two flash tanks, F101 to separate out the non-condensibles and F102 to further separate the benzene-toluene mixture to improve the benzene purity. Note that typically a distillation column is required to obtain high purity benzene but that is beyond the scope of this workshop. The non-condensibles separated out in F101 will be partially recycled back to M101 and the rest will be either purged or combusted for power generation.We will assume ideal gas for this flowsheet. The properties required for this module are available in the same directory:

hda_ideal_VLE.py

hda_reaction.py

The state variables chosen for the property package are flows of component by phase, temperature and pressure. The components considered are: toluene, hydrogen, benzene and methane. Therefore, every stream has 8 flow variables, 1 temperature and 1 pressure variable.

1 Importing Modules

1.1 Importing required Pyomo and IDAES components

To construct a flowsheet, we will need several components from the Pyomo and IDAES package. Let us first import the following components from Pyomo:

Constraint (to write constraints)

Var (to declare variables)

ConcreteModel (to create the concrete model object)

Expression (to evaluate values as a function of variables defined in the model)

Objective (to define an objective function for optimization)

SolverFactory (to solve the problem)

TransformationFactory (to apply certain transformations)

Arc (to connect two unit models)

SequentialDecomposition (to initialize the flowsheet in a sequential mode)

For further details on these components, please refer to the Pyomo documentation: https://Pyomo.readthedocs.io/en/stable/

From IDAES, we will be needing the FlowsheetBlock and the following unit models:

Feed

Mixer

Heater

StoichiometricReactor

Flash

Separator (splitter)

PressureChanger

Product

Inline Exercise:

Now, import the remaining unit models highlighted in blue above and run the cell using `Shift+Enter` after typing in the code.

We will also be needing some utility tools to put together the flowsheet and calculate the degrees of freedom.

1.2 Importing required thermo and reaction package

The final set of imports are to import the thermo and reaction package for the HDA process. We have created a custom thermo package that assumes Ideal Gas with support for VLE.

The reaction package here is very simple as we will be using only a StochiometricReactor and the reaction package consists of the stochiometric coefficients for the reaction and the parameter for the heat of reaction.

Let us import the following modules and they are in the same directory as this jupyter notebook:

- hda_ideal_VLE as thermo_props

- hda_reaction as reaction_props

2 Constructing the Flowsheet

We have now imported all the components, unit models, and property modules we need to construct a flowsheet. Let us create a ConcreteModel and add the flowsheet block.

We now need to add the property packages to the flowsheet. Unlike Module 1, where we only had a thermo property package, for this flowsheet we will also need to add a reaction property package.

2.1 Adding Unit Models

Let us start adding the unit models we have imported to the flowsheet. Here, we are adding the Feed (assigned a name I101 for Inlet), Mixer (assigned a name M101) and a Heater (assigned a name H101). Note that, all unit models need to be given a property package argument. In addition to that, there are several arguments depending on the unit model, please refer to the documentation for more details (https://idaes-pse.readthedocs.io/en/stable/reference_guides/model_libraries/generic/unit_models/index.html). For example, the Mixer unit model here must be specified the number of inlets that it will take in and the Heater can have specific settings enabled such as has_pressure_change or has_phase_equilibrium.

Let us now add the Flash(assign the name F101) and pass the following arguments:

- ”property_package”: m.fs.thermo_params

- ”has_heat_transfer”: True

- ”has_pressure_change”: False

Let us now add the Splitter(S101) with specific names for its output (purge and recycle), PressureChanger(C101) and the second Flash(F102).

Last, we will add the three Product blocks (P101, P102, P103). We use Feed blocks and Product blocks for convenience with reporting stream summaries and consistency

2.2 Connecting Unit Models using Arcs

We have now added all the unit models we need to the flowsheet. However, we have not yet specified how the units are to be connected. To do this, we will be using the Arc which is a Pyomo component that takes in two arguments: source and destination. Let us connect the outlet of the inlets (I101, I102) to the inlet of the mixer (M101) and outlet of the mixer to the inlet of the heater(H101).

We will now be connecting the rest of the flowsheet as shown below. Notice how the outlet names are different for the flash tanks F101 and F102 as they have a vapor and a liquid outlet.

Last we will connect the outlet streams to the inlets of the Product blocks (P101, P102, P103)

We have now connected the unit model block using the arcs. However, each of these arcs link to ports on the two unit models that are connected. In this case, the ports consist of the state variables that need to be linked between the unit models. Pyomo provides a convenient method to write these equality constraints for us between two ports and this is done as follows:

2.3 Adding expressions to compute purity and operating costs

In this section, we will add a few Expressions that allows us to evaluate the performance. Expressions provide a convenient way of calculating certain values that are a function of the variables defined in the model. For more details on Expressions, please refer to: https://pyomo.readthedocs.io/en/stable/explanation/modeling/network.html.

For this flowsheet, we are interested in computing the purity of the product Benzene stream (i.e. the mole fraction) and the operating cost which is a sum of the cooling and heating cost.

Let us first add an Expression to compute the mole fraction of benzene in the vap_outlet of F102 which is our product stream. Please note that the var flow_mol_phase_comp has the index - [time, phase, component]. As this is a steady-state flowsheet, the time index by default is 0. The valid phases are [“Liq”, “Vap”]. Similarly the valid component list is [“benzene”, “toluene”, “hydrogen”, “methane”].

Now, let us add an expression to compute the cooling cost assuming a cost of 0.212E-4 $/kW. Note that cooling utility is required for the reactor (R101) and the first flash (F101).

Now, let us add an expression to compute the heating cost assuming the utility cost as follows:

- 2.2E-4 dollars/kW for H101

- 1.9E-4 dollars/kW for F102

Note that the heat duty is in units of watt (J/s).

Let us now add an expression to compute the total operating cost per year which is basically the sum of the cooling and heating cost we defined above.

4 Specifying the Model

4.1 Fixing feed conditions

Let us first check how many degrees of freedom exist for this flowsheet using the degrees_of_freedom tool we imported earlier.

We will now be fixing the toluene feed (I101) stream to the conditions shown in the flowsheet above. Please note that though this is a pure toluene feed, the remaining components are still assigned a very small non-zero value to help with convergence and initializing.

Similarly, let us fix the hydrogen feed (I102) to the following conditions in the next cell:

- FH2 = 0.30 mol/s

- FCH4 = 0.02 mol/s

- Remaining components = 1e-5 mol/s

- T = 303.2 K

- P = 350000 Pa

4.2 Fixing unit model specifications

Now that we have fixed our inlet feed conditions, we will now be fixing the operating conditions for the unit models in the flowsheet. Let us set set the H101 outlet temperature to 600 K.

For the StoichiometricReactor, we have to define the conversion in terms of toluene. This requires us to create a new variable for specifying the conversion and adding a Constraint that defines the conversion with respect to toluene. The second degree of freedom for the reactor is to define the heat duty. In this case, let us assume the reactor to be adiabatic i.e. Q = 0.

The Flash conditions for F101 can be set as follows.

Let us fix the purge split fraction to 20% and the outlet pressure of the compressor is set to 350000 Pa.

5 Initializing the Model

When a flowsheet contains a recycle loop, the outlet of a downstream unit becomes the inlet of an upstream unit, creating a cyclic dependency that prevents straightforward calculation of all stream conditions. The tear‐stream method is necessary because it “breaks” this loop: you select one recycle stream as the tear, assign it an initial guess, and then solve the rest of the flowsheet as if it were acyclic. Once the downstream units compute their outputs, you compare the calculated value of the torn stream to your initial guess and iteratively adjust until they coincide. Without tearing, the solver cannot establish a proper topological sequence or drive the recycle to convergence, making initialization—and ultimately steady‐state convergence—impossible.

It is important to determine the tear stream for a flowsheet which will be demonstrated below.

Currently, there are two methods of initializing a full flowsheet: using the sequential decomposition tool, or manually propagating through the flowsheet. Both methods will be shown.

5.1 Sequential Decomposition

This section will demonstrate how to use the built-in sequential decomposition tool to initialize our flowsheet. Sequential Decomposition is a tool from Pyomo where the documentation can be found here https://Pyomo.readthedocs.io/en/stable/explanation/modeling/network.html#sequential-decomposition

Let us first create an object for the SequentialDecomposition and specify our options for this. We can also create a graph for our flowsheet to determine the tear set and order.

Which is the tear stream? Display tear set and order

What sequence did the SD tool determine to solve this flowsheet with the least number of tears?

fs.I101

fs.R101

fs.F101

fs.S101

fs.C101

fs.M101

The SequentialDecomposition tool has determined that the tear stream is the mixer outlet. You can see this shown in the picture of the flowsheet above as the outlet of the mixer as the two lines crossing it identifying it as the tear stream. We will need to provide a reasonable guess for this.

Next, we need to tell the tool how to initialize a particular unit. We will be writing a python function which takes in a “unit” and calls the initialize method on that unit.

We are now ready to initialize our flowsheet in a sequential mode. Note that we specifically set the iteration limit to be 5 as we are trying to use this tool only to get a good set of initial values such that IPOPT can then take over and solve this flowsheet for us.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I101.properties: Starting initialization routine

2025-11-25 12:36:40 [INFO] idaes.init.fs.I101.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I101.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I101.properties: State variable initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I101.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I101.properties: Property initialization routine finished.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I102.properties: Starting initialization routine

2025-11-25 12:36:40 [INFO] idaes.init.fs.I102.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I102.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I102.properties: State variable initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I102.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.I102.properties: Property initialization routine finished.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.H101.control_volume.properties_out: Property initialization routine finished.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.R101.control_volume.properties_out: Property initialization routine finished.

WARNING: Loading a SolverResults object with a warning status into

model.name="fs.R101";

- termination condition: infeasible

- message from solver: Ipopt 3.13.2\x3a Converged to a locally infeasible

point. Problem may be infeasible.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:40 [INFO] idaes.init.fs.F101.control_volume.properties_out: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.mixed_state: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.mixed_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.mixed_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.mixed_state: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.mixed_state: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.mixed_state: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.purge_state: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.purge_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.purge_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.purge_state: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.purge_state: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.purge_state: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.recycle_state: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.recycle_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.recycle_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.recycle_state: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.recycle_state: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101.recycle_state: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.S101: Initialization Step 2 Complete: optimal - <undefined>

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.F102.control_volume.properties_out: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.C101.control_volume.properties_out: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P101.properties: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.P101.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P101.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P101.properties: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P101.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P101.properties: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P102.properties: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.P102.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P102.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P102.properties: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P102.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P102.properties: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P103.properties: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.P103.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P103.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P103.properties: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P103.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.P103.properties: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_1_state: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_1_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_1_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_1_state: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_1_state: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_1_state: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_2_state: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_2_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_2_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_2_state: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_2_state: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_2_state: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_3_state: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_3_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_3_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_3_state: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_3_state: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.inlet_3_state: Property initialization routine finished.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.mixed_state: Starting initialization routine

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.mixed_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.mixed_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.mixed_state: State variable initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.mixed_state: Phase equilibrium initialization completed.

2025-11-25 12:36:41 [INFO] idaes.init.fs.M101.mixed_state: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.M101: Initialization Complete: optimal - <undefined>

2025-11-25 12:36:42 [INFO] idaes.init.fs.I101.properties: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.I101.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I101.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I101.properties: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I101.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I101.properties: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I102.properties: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.I102.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I102.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I102.properties: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I102.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.I102.properties: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.H101.control_volume.properties_out: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.R101.control_volume.properties_out: Property initialization routine finished.

WARNING: Loading a SolverResults object with a warning status into

model.name="fs.R101";

- termination condition: infeasible

- message from solver: Ipopt 3.13.2\x3a Converged to a locally infeasible

point. Problem may be infeasible.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.F101.control_volume.properties_out: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.mixed_state: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.mixed_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.mixed_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.mixed_state: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.mixed_state: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.mixed_state: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.purge_state: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.purge_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.purge_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.purge_state: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.purge_state: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.purge_state: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.recycle_state: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.recycle_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.recycle_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.recycle_state: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.recycle_state: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101.recycle_state: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.S101: Initialization Step 2 Complete: optimal - <undefined>

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:42 [INFO] idaes.init.fs.C101.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.C101.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.C101.control_volume.properties_out: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_1_state: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_1_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_1_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_1_state: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_1_state: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_1_state: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_2_state: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_2_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_2_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_2_state: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_2_state: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_2_state: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_3_state: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_3_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_3_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_3_state: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_3_state: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.inlet_3_state: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.mixed_state: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.mixed_state: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.mixed_state: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.mixed_state: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.mixed_state: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101.mixed_state: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.M101: Initialization Complete: optimal - <undefined>

2025-11-25 12:36:43 [INFO] idaes.init.fs.P103.properties: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.P103.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P103.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P103.properties: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P103.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P103.properties: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_in: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_in: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_in: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_in: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_in: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_in: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_out: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_out: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_out: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_out: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_out: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.F102.control_volume.properties_out: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P101.properties: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.P101.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P101.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P101.properties: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P101.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P101.properties: Property initialization routine finished.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P102.properties: Starting initialization routine

2025-11-25 12:36:43 [INFO] idaes.init.fs.P102.properties: Bubble, dew, and critical point initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P102.properties: Equilibrium temperature initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P102.properties: State variable initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P102.properties: Phase equilibrium initialization completed.

2025-11-25 12:36:43 [INFO] idaes.init.fs.P102.properties: Property initialization routine finished.

5.2 Manual Propagation Method

This method uses a more direct approach to initialize the flowsheet, utilizing the updated initializer method and propagating manually through the flowsheet and solving for the tear stream directly.

Lets first import a helper function that will help us manually propagate and step through the flowsheet

Now we can setup our initial guesses for the tear stream which we know is the outlet of the Mixer or the inlet of the Heater. We can use the same initial guesses used in the first method. We also want to ensure that the degrees of freedom are consistent while we manually initialize the model.

We will first ensure that are current degrees of freedom is still zero

Now we can manually deactivate the tear stream, creating a separation between the Mixer and Heater. This should reduce the degrees of freedom by 10 since the inlet of the Heater now contains no values to solve the unit model. To deactivate a stream, simply use m.fs.s03_expanded.deactivate(). This expanded stream is just a different version of the Arc stream that is able to be deactivated.

Now we can provide the Heater inlet 10 guess values to bring the degrees of freedom back to 0 and start the manual initialization process. We can run this convenient loop to assign each of these guesses to the inlet of the heater.

The next step is to manually initialize each unit model starting from the Heater and then propagate the connection between it and the next unit model. This manual process ensures a strict order to the user’s specification if that is desired. The current standard for initializing a unit model is to use an initializer object most compatible for that unit model. This can most often be done by utilizing the default_initializer() method attached to the unit model and then to call the initialize() method with the unit model as the argument.

Now we solve the system to allow the outlet of the mixer to reach a converged congruence with the inlet of the heater.

Ipopt 3.13.2: linear_solver="ma57"

max_iter=300

nlp_scaling_method="user-scaling"

tol=1e-08

option_file_name="C:\Users\Tanner\AppData\Local\Temp\tmpoctkmbii\unknown.14248.22376.opt"

Using option file "C:\Users\Tanner\AppData\Local\Temp\tmpoctkmbii\unknown.14248.22376.opt".

******************************************************************************

This program contains Ipopt, a library for large-scale nonlinear optimization.

Ipopt is released as open source code under the Eclipse Public License (EPL).

For more information visit http://projects.coin-or.org/Ipopt

This version of Ipopt was compiled from source code available at

https://github.com/IDAES/Ipopt as part of the Institute for the Design of

Advanced Energy Systems Process Systems Engineering Framework (IDAES PSE

Framework) Copyright (c) 2018-2019. See https://github.com/IDAES/idaes-pse.

This version of Ipopt was compiled using HSL, a collection of Fortran codes

for large-scale scientific computation. All technical papers, sales and

publicity material resulting from use of the HSL codes within IPOPT must

contain the following acknowledgement:

HSL, a collection of Fortran codes for large-scale scientific

computation. See http://www.hsl.rl.ac.uk.

******************************************************************************

This is Ipopt version 3.13.2, running with linear solver ma57.

Number of nonzeros in equality constraint Jacobian...: 920

Number of nonzeros in inequality constraint Jacobian.: 0

Number of nonzeros in Lagrangian Hessian.............: 456

Total number of variables............................: 218

variables with only lower bounds: 56

variables with lower and upper bounds: 155

variables with only upper bounds: 0

Total number of equality constraints.................: 218

Total number of inequality constraints...............: 0

inequality constraints with only lower bounds: 0

inequality constraints with lower and upper bounds: 0

inequality constraints with only upper bounds: 0

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

0 0.0000000e+00 3.74e+03 1.00e+00 -1.0 0.00e+00 - 0.00e+00 0.00e+00 0

Reallocating memory for MA57: lfact (10193)

1r 0.0000000e+00 3.74e+03 9.99e+02 3.6 0.00e+00 - 0.00e+00 3.17e-07R 3

2r 0.0000000e+00 6.21e+04 1.21e+03 3.6 3.74e+06 - 3.68e-03 3.56e-04f 1

3r 0.0000000e+00 5.77e+04 1.09e+05 3.6 5.16e+05 - 9.43e-02 4.63e-03f 1

4r 0.0000000e+00 5.24e+04 6.21e+04 3.6 3.34e+03 - 2.55e-01 9.98e-02f 1

5r 0.0000000e+00 6.56e+04 1.25e+05 3.6 1.51e+02 - 6.91e-01 4.02e-01f 1

6r 0.0000000e+00 4.50e+04 2.67e+04 3.6 3.07e+01 - 1.00e+00 7.13e-01f 1

7r 0.0000000e+00 1.83e+04 7.35e+03 3.6 3.08e+01 - 1.00e+00 1.00e+00f 1

8r 0.0000000e+00 3.31e+04 4.68e+03 2.9 3.73e+01 - 7.83e-01 8.25e-01f 1

9r 0.0000000e+00 1.06e+04 6.58e+02 2.9 2.24e+01 - 1.00e+00 1.00e+00f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

10r 0.0000000e+00 6.29e+03 4.93e+02 2.9 2.70e+01 - 1.00e+00 1.00e+00h 1

11r 0.0000000e+00 5.23e+04 5.25e+02 2.2 2.33e+01 - 9.63e-01 9.78e-01f 1

12r 0.0000000e+00 7.01e+03 1.04e+02 2.2 2.10e+01 - 1.00e+00 1.00e+00f 1

13r 0.0000000e+00 8.17e+02 1.95e+01 2.2 5.26e+00 - 1.00e+00 1.00e+00f 1

14r 0.0000000e+00 5.65e+03 7.52e+02 1.5 1.79e+01 - 8.36e-01 9.57e-01f 1

15r 0.0000000e+00 1.39e+04 5.80e+02 1.5 7.56e+01 - 7.87e-01 5.50e-01f 1

16r 0.0000000e+00 1.86e+04 4.51e+02 1.5 1.21e+01 - 6.10e-01 1.00e+00f 1

17r 0.0000000e+00 1.25e+04 2.51e+02 1.5 1.27e+01 - 7.28e-01 1.00e+00f 1

18r 0.0000000e+00 8.69e+02 4.46e+01 1.5 9.42e+00 - 1.00e+00 1.00e+00h 1

19r 0.0000000e+00 2.75e+02 1.30e+00 1.5 2.78e+00 - 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

20r 0.0000000e+00 3.71e+03 2.13e+02 0.8 1.88e+01 - 9.33e-01 9.68e-01f 1

21r 0.0000000e+00 9.91e+01 1.22e+02 0.8 1.24e-01 2.0 1.00e+00 1.00e+00f 1

22r 0.0000000e+00 2.87e+01 1.01e+03 0.8 4.55e-01 1.5 3.90e-01 9.98e-01H 1

23r 0.0000000e+00 4.95e+02 1.46e+02 0.8 4.53e-01 1.0 1.00e+00 9.27e-01f 1

24r 0.0000000e+00 4.75e+02 3.38e+02 0.8 4.95e-01 1.5 6.73e-01 8.53e-01f 1

25r 0.0000000e+00 2.04e+02 7.82e+01 0.8 7.99e-02 2.8 1.00e+00 1.00e+00f 1

26r 0.0000000e+00 2.86e+02 1.37e+02 0.8 9.62e-01 2.3 2.38e-01 2.31e-01f 1

27r 0.0000000e+00 2.57e+02 7.76e+02 0.8 7.36e-01 1.8 4.15e-01 7.40e-02f 1

28r 0.0000000e+00 2.55e+02 7.67e+02 0.8 3.59e+02 - 2.06e-02 8.24e-03f 2

29r 0.0000000e+00 3.58e+02 5.95e+01 0.8 1.21e-01 1.4 1.00e+00 1.00e+00f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

30r 0.0000000e+00 8.66e+02 2.43e+02 0.8 6.93e+01 - 9.31e-01 4.48e-01f 2

31r 0.0000000e+00 7.82e+02 2.67e+02 0.8 5.52e+00 0.9 8.90e-02 9.64e-02h 1

32r 0.0000000e+00 6.93e+02 1.87e+02 0.8 2.84e+01 - 5.79e-02 1.48e-01h 1

33r 0.0000000e+00 5.58e+02 1.23e+02 0.8 2.39e+01 - 2.97e-01 3.32e-01f 1

34r 0.0000000e+00 4.53e+02 2.25e+02 0.8 1.58e+01 - 1.41e-01 2.10e-01f 1

35r 0.0000000e+00 4.31e+02 1.86e+02 0.8 1.74e+01 - 2.72e-02 5.15e-02h 1

36r 0.0000000e+00 4.28e+02 3.00e+02 0.8 4.39e+01 - 1.73e-03 5.76e-03h 1

37r 0.0000000e+00 4.28e+02 2.99e+02 0.8 1.11e+03 - 2.19e-05 2.25e-04h 1

38r 0.0000000e+00 4.28e+02 6.92e+02 0.8 2.39e+02 1.3 2.42e-03 1.96e-04f 1

39r 0.0000000e+00 4.12e+02 1.12e+04 0.8 1.90e+01 - 7.18e-01 3.76e-02f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

40r 0.0000000e+00 1.29e+02 2.87e+02 0.8 1.04e+01 - 1.00e+00 1.00e+00f 1

41r 0.0000000e+00 4.97e+01 7.12e+02 0.8 5.85e+00 - 5.86e-01 6.18e-01h 1

42r 0.0000000e+00 1.60e+00 1.99e+02 0.8 7.12e-01 0.8 1.00e+00 1.00e+00f 1

43r 0.0000000e+00 2.18e+01 1.63e+02 0.1 6.04e+01 0.4 1.22e-02 7.09e-03f 1

44r 0.0000000e+00 7.21e+03 1.05e+03 0.1 1.64e+02 - 1.83e-01 7.12e-01f 1

45r 0.0000000e+00 6.31e+03 7.50e+02 0.1 5.95e+01 - 1.09e-01 1.68e-01f 1

46r 0.0000000e+00 6.22e+03 1.41e+03 0.1 9.02e+01 - 8.19e-04 1.38e-02f 1

47r 0.0000000e+00 6.22e+03 1.41e+03 0.1 1.27e+02 0.8 1.98e-03 9.14e-04h 1

48r 0.0000000e+00 6.21e+03 1.57e+03 0.1 2.55e+02 0.3 1.66e-05 7.85e-04h 1

49r 0.0000000e+00 6.18e+03 1.56e+03 0.1 2.15e+01 0.7 2.64e-03 4.99e-03h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

50r 0.0000000e+00 6.18e+03 1.60e+03 0.1 1.55e+02 0.3 2.53e-05 2.61e-04h 1

51r 0.0000000e+00 6.18e+03 1.67e+03 0.1 7.60e+01 1.6 1.06e-02 3.63e-04h 1

52r 0.0000000e+00 5.80e+03 1.65e+03 0.1 2.59e+01 - 3.10e-02 6.80e-02f 1

53r 0.0000000e+00 5.29e+03 1.04e+03 0.1 3.13e+01 - 8.78e-01 6.14e-01f 1

54r 0.0000000e+00 2.06e+03 3.00e+02 0.1 3.76e+01 - 7.50e-01 1.00e+00h 1

55r 0.0000000e+00 5.02e+01 1.17e+02 0.1 1.26e+01 - 1.00e+00 1.00e+00h 1

56r 0.0000000e+00 4.11e+01 1.08e+02 0.1 4.23e+00 - 2.42e-01 1.84e-01h 1

57r 0.0000000e+00 2.12e+01 5.27e+01 0.1 1.15e+00 - 7.37e-01 8.32e-01h 1

58r 0.0000000e+00 4.74e+01 3.85e+01 0.1 1.60e+00 - 9.93e-01 1.00e+00f 1

59r 0.0000000e+00 1.17e+01 3.25e+01 0.1 1.40e+00 - 1.00e+00 1.00e+00f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

60r 0.0000000e+00 1.21e+03 4.46e+01 -0.6 5.97e+01 - 7.60e-01 6.94e-01f 1

61r 0.0000000e+00 1.54e+03 4.60e+00 -0.6 9.23e+01 - 1.00e+00 1.00e+00f 1

62r 0.0000000e+00 1.21e+01 9.28e+00 -0.6 4.59e+01 - 1.00e+00 1.00e+00h 1

63r 0.0000000e+00 1.83e+00 9.35e-02 -0.6 2.84e+00 - 1.00e+00 1.00e+00h 1

64r 0.0000000e+00 1.11e+03 6.94e+01 -1.3 7.51e+01 - 9.02e-01 9.81e-01f 1

65r 0.0000000e+00 7.93e+00 9.52e-01 -1.3 2.38e+01 - 1.00e+00 1.00e+00h 1

66r 0.0000000e+00 1.78e+00 1.07e-01 -1.3 8.10e-01 - 1.00e+00 1.00e+00h 1

67r 0.0000000e+00 2.18e-01 1.01e-05 -1.3 3.94e-03 - 1.00e+00 1.00e+00h 1

68r 0.0000000e+00 1.15e+03 4.78e+01 -4.5 7.86e+01 - 7.94e-01 8.05e-01f 1

69r 0.0000000e+00 5.20e+02 1.43e+02 -4.5 2.20e+01 - 9.21e-01 5.55e-01h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

70r 0.0000000e+00 2.62e+02 4.30e+02 -4.5 1.21e-02 1.1 9.09e-01 4.96e-01h 1

71r 0.0000000e+00 6.29e+01 1.51e+02 -4.5 1.25e-02 0.6 9.00e-01 7.60e-01h 1

72r 0.0000000e+00 9.72e+00 5.07e+01 -4.5 5.71e-02 0.2 9.11e-01 8.46e-01h 1

73r 0.0000000e+00 2.40e-01 8.98e-01 -4.5 1.58e-01 -0.3 1.00e+00 9.91e-01h 1

74r 0.0000000e+00 3.60e-01 1.74e+02 -4.5 3.96e+03 - 6.95e-03 2.59e-03f 1

75r 0.0000000e+00 8.17e-01 3.02e+02 -4.5 9.81e+00 - 7.96e-02 1.55e-02h 1

76r 0.0000000e+00 2.96e+02 1.34e+03 -4.5 3.56e+00 - 9.74e-02 3.29e-01h 1

77r 0.0000000e+00 2.24e+02 1.38e+03 -4.5 2.48e-02 -0.8 1.00e+00 2.45e-01h 1

78r 0.0000000e+00 1.29e+03 6.57e+02 -4.5 1.82e+00 - 6.97e-01 1.00e+00h 1

79r 0.0000000e+00 2.01e+02 1.01e+02 -4.5 2.12e+00 - 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

80r 0.0000000e+00 4.78e+00 7.47e-01 -4.5 3.32e-01 - 1.00e+00 1.00e+00h 1

81r 0.0000000e+00 2.94e+00 2.75e-02 -4.5 2.59e-01 - 1.00e+00 1.00e+00h 1

82r 0.0000000e+00 2.79e-01 2.57e-03 -4.5 2.99e-02 - 1.00e+00 1.00e+00h 1

83r 0.0000000e+00 2.79e-01 4.06e-04 -4.5 4.57e-03 - 1.00e+00 1.00e+00h 1

84r 0.0000000e+00 2.79e-01 1.25e-07 -4.5 8.34e-05 - 1.00e+00 1.00e+00h 1

85r 0.0000000e+00 5.26e+01 1.09e+01 -6.8 7.12e-01 - 9.31e-01 8.92e-01f 1

86r 0.0000000e+00 2.95e+01 4.47e+02 -6.8 1.59e-01 - 7.12e-01 4.40e-01h 1

87r 0.0000000e+00 7.70e+00 1.01e+02 -6.8 9.53e-02 - 8.78e-01 7.65e-01h 1

88r 0.0000000e+00 3.45e+00 1.42e+02 -6.8 9.16e-02 - 1.00e+00 7.55e-01h 1

89r 0.0000000e+00 9.20e-01 4.87e+01 -6.8 1.08e-01 - 8.60e-01 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

90r 0.0000000e+00 8.31e-01 1.80e-01 -6.8 1.38e-01 - 1.00e+00 1.00e+00h 1

91r 0.0000000e+00 2.83e-01 1.84e-01 -6.8 7.34e-02 - 1.00e+00 1.00e+00h 1

92r 0.0000000e+00 2.83e-01 4.21e+02 -6.8 9.27e-01 - 1.19e-01 4.48e-03h 6

93r 0.0000000e+00 2.83e-01 1.51e+02 -6.8 9.89e-06 -1.3 1.00e+00 1.03e-01h 1

94r 0.0000000e+00 2.83e-01 3.45e+02 -6.8 1.02e+00 - 1.44e-01 2.36e-02h 3

95r 0.0000000e+00 2.83e-01 2.09e+01 -6.8 6.98e-03 -1.7 3.75e-02 2.48e-02h 2

96r 0.0000000e+00 2.83e-01 7.23e+00 -6.8 5.65e-04 -2.2 9.81e-01 1.00e+00h 1

97r 0.0000000e+00 1.20e+01 2.06e+02 -6.8 1.57e+00 - 1.00e+00 3.33e-01h 2

98r 0.0000000e+00 1.19e+01 2.37e+01 -6.8 1.56e-02 - 1.00e+00 5.65e-03h 8

99r 0.0000000e+00 1.18e+01 2.23e+01 -6.8 1.79e-02 - 1.00e+00 7.81e-03h 8

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

100r 0.0000000e+00 1.18e+01 2.16e+01 -6.8 1.76e-02 - 1.00e+00 1.95e-03h 10

101r 0.0000000e+00 1.18e+01 2.14e+01 -6.8 1.76e-02 - 1.00e+00 9.77e-04h 11

102r 0.0000000e+00 1.18e+01 2.13e+01 -6.8 1.76e-02 - 1.00e+00 4.88e-04h 12

103r 0.0000000e+00 2.90e-01 3.50e-04 -6.8 1.76e-02 - 1.00e+00 1.00e+00h 1

104r 0.0000000e+00 7.03e+00 2.14e+02 -6.8 4.02e-01 - 5.84e-01 1.00e+00h 1

105r 0.0000000e+00 2.96e-01 5.54e+01 -6.8 7.32e-02 - 2.26e-01 1.00e+00h 1

106r 0.0000000e+00 2.96e-01 8.03e-05 -6.8 1.47e-04 -2.7 1.00e+00 1.00e+00h 1

107r 0.0000000e+00 2.95e-01 4.46e+01 -6.8 1.04e-01 - 1.00e+00 5.00e-01h 2

108r 0.0000000e+00 2.95e-01 1.34e-02 -6.8 1.91e-02 - 1.00e+00 1.00e+00h 1

109r 0.0000000e+00 2.94e-01 1.41e-03 -6.8 3.97e-02 - 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

110r 0.0000000e+00 2.94e-01 9.14e-04 -6.8 2.67e-02 - 1.00e+00 1.00e+00h 1

111r 0.0000000e+00 2.94e-01 4.70e-05 -6.8 1.04e-03 - 1.00e+00 1.00e+00h 1

112r 0.0000000e+00 2.94e-01 1.32e-07 -6.8 7.16e-04 - 1.00e+00 1.00e+00h 1

113r 0.0000000e+00 2.94e-01 1.82e-12 -6.8 2.28e-06 - 1.00e+00 1.00e+00h 1

114r 0.0000000e+00 9.46e-01 5.08e+00 -9.0 2.12e-01 - 6.64e-01 6.35e-01h 1

115r 0.0000000e+00 1.29e+01 9.86e+00 -9.0 5.14e-01 - 7.92e-01 7.53e-01h 1

116r 0.0000000e+00 6.76e+00 1.53e+02 -9.0 2.57e-01 - 8.31e-01 6.76e-01h 1

117r 0.0000000e+00 8.96e+00 2.11e+00 -9.0 1.62e-01 - 1.00e+00 1.00e+00h 1

118r 0.0000000e+00 8.94e-01 8.15e-01 -9.0 8.76e-02 - 1.00e+00 1.00e+00h 1

119r 0.0000000e+00 5.50e-01 2.30e-02 -9.0 1.13e-01 - 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

120r 0.0000000e+00 2.99e-01 1.49e-04 -9.0 1.27e-02 - 1.00e+00 1.00e+00h 1

121r 0.0000000e+00 2.98e-01 2.05e-05 -9.0 1.10e-02 - 1.00e+00 1.00e+00h 1

122r 0.0000000e+00 2.98e-01 2.86e-08 -9.0 5.44e-04 - 1.00e+00 1.00e+00h 1

Number of Iterations....: 122

(scaled) (unscaled)

Objective...............: 0.0000000000000000e+00 0.0000000000000000e+00

Dual infeasibility......: 4.6276843335396955e-07 4.6276843335396955e-07

Constraint violation....: 2.9835465732216782e-01 2.9835465732216782e-01

Complementarity.........: 9.0909090909100423e-10 9.0909090909100423e-10

Overall NLP error.......: 2.9835465732216782e-01 2.9835465732216782e-01

Number of objective function evaluations = 193

Number of objective gradient evaluations = 3

Number of equality constraint evaluations = 193

Number of inequality constraint evaluations = 0

Number of equality constraint Jacobian evaluations = 125

Number of inequality constraint Jacobian evaluations = 0

Number of Lagrangian Hessian evaluations = 123

Total CPU secs in IPOPT (w/o function evaluations) = 0.161

Total CPU secs in NLP function evaluations = 0.016

EXIT: Converged to a point of local infeasibility. Problem may be infeasible.

Now that the flowsheet is initialized, we can unfix the guesses for the Heater and reactive the tear stream to complete the final solve.

The DOF is 0 after unfixing the values and reactivating the tear stream

6 Solving the Model

We have now initialized the flowsheet. Lets set up some solving options before simulating the flowsheet. We want to specify the scaling method, number of iterations, and tolerance. More specific or advanced options can be found at the documentation for IPOPT https://coin-or.github.io/Ipopt/OPTIONS.html

Ipopt 3.13.2: linear_solver="ma57"

max_iter=1000

nlp_scaling_method="user-scaling"

tol=1e-08

option_file_name="C:\Users\Tanner\AppData\Local\Temp\tmpg07cmjii\unknown.14248.22376.opt"

Using option file "C:\Users\Tanner\AppData\Local\Temp\tmpg07cmjii\unknown.14248.22376.opt".

******************************************************************************

This program contains Ipopt, a library for large-scale nonlinear optimization.

Ipopt is released as open source code under the Eclipse Public License (EPL).

For more information visit http://projects.coin-or.org/Ipopt

This version of Ipopt was compiled from source code available at

https://github.com/IDAES/Ipopt as part of the Institute for the Design of

Advanced Energy Systems Process Systems Engineering Framework (IDAES PSE

Framework) Copyright (c) 2018-2019. See https://github.com/IDAES/idaes-pse.

This version of Ipopt was compiled using HSL, a collection of Fortran codes

for large-scale scientific computation. All technical papers, sales and

publicity material resulting from use of the HSL codes within IPOPT must

contain the following acknowledgement:

HSL, a collection of Fortran codes for large-scale scientific

computation. See http://www.hsl.rl.ac.uk.

******************************************************************************

This is Ipopt version 3.13.2, running with linear solver ma57.

Number of nonzeros in equality constraint Jacobian...: 920

Number of nonzeros in inequality constraint Jacobian.: 0

Number of nonzeros in Lagrangian Hessian.............: 456

Total number of variables............................: 218

variables with only lower bounds: 56

variables with lower and upper bounds: 155

variables with only upper bounds: 0

Total number of equality constraints.................: 218

Total number of inequality constraints...............: 0

inequality constraints with only lower bounds: 0

inequality constraints with lower and upper bounds: 0

inequality constraints with only upper bounds: 0

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

0 0.0000000e+00 3.74e+03 1.00e+00 -1.0 0.00e+00 - 0.00e+00 0.00e+00 0

Reallocating memory for MA57: lfact (10193)

1r 0.0000000e+00 3.74e+03 9.99e+02 3.6 0.00e+00 - 0.00e+00 3.17e-07R 3

2r 0.0000000e+00 6.21e+04 1.21e+03 3.6 3.74e+06 - 3.68e-03 3.56e-04f 1

3r 0.0000000e+00 5.77e+04 1.01e+05 3.6 5.16e+05 - 8.85e-02 4.63e-03f 1

4r 0.0000000e+00 5.27e+04 7.54e+04 3.6 3.55e+03 - 2.53e-01 9.39e-02f 1

5r 0.0000000e+00 6.46e+04 1.25e+05 3.6 1.62e+02 - 6.86e-01 3.91e-01f 1

6r 0.0000000e+00 4.60e+04 2.59e+04 3.6 3.07e+01 - 1.00e+00 7.29e-01f 1

7r 0.0000000e+00 1.41e+04 8.03e+03 3.6 3.17e+01 - 1.00e+00 1.00e+00f 1

8r 0.0000000e+00 3.34e+04 6.37e+03 2.9 3.71e+01 - 7.68e-01 8.25e-01f 1

9r 0.0000000e+00 1.19e+04 7.40e+02 2.9 2.24e+01 - 1.00e+00 1.00e+00f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

10r 0.0000000e+00 6.30e+03 4.59e+02 2.9 2.35e+01 - 1.00e+00 1.00e+00h 1

11r 0.0000000e+00 5.23e+04 5.45e+02 2.2 2.33e+01 - 9.62e-01 9.77e-01f 1

12r 0.0000000e+00 7.00e+03 1.04e+02 2.2 2.11e+01 - 1.00e+00 1.00e+00f 1

13r 0.0000000e+00 7.13e+02 1.92e+01 2.2 5.17e+00 - 1.00e+00 1.00e+00f 1

14r 0.0000000e+00 5.67e+03 7.52e+02 1.5 1.80e+01 - 8.36e-01 9.57e-01f 1

15r 0.0000000e+00 1.39e+04 5.79e+02 1.5 7.56e+01 - 7.87e-01 5.50e-01f 1

16r 0.0000000e+00 1.86e+04 4.46e+02 1.5 1.21e+01 - 6.13e-01 1.00e+00f 1

17r 0.0000000e+00 1.24e+04 2.49e+02 1.5 1.26e+01 - 7.29e-01 1.00e+00f 1

18r 0.0000000e+00 8.65e+02 4.42e+01 1.5 9.39e+00 - 1.00e+00 1.00e+00h 1

19r 0.0000000e+00 2.73e+02 1.31e+00 1.5 2.73e+00 - 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

20r 0.0000000e+00 3.72e+03 2.13e+02 0.8 1.88e+01 - 9.33e-01 9.68e-01f 1

21r 0.0000000e+00 9.91e+01 1.22e+02 0.8 1.24e-01 2.0 1.00e+00 1.00e+00f 1

22r 0.0000000e+00 2.89e+01 1.01e+03 0.8 4.57e-01 1.5 3.88e-01 9.92e-01H 1

23r 0.0000000e+00 4.92e+02 1.65e+02 0.8 4.52e-01 1.0 1.00e+00 9.06e-01f 1

24r 0.0000000e+00 4.89e+02 3.27e+02 0.8 4.93e-01 1.5 6.74e-01 8.51e-01f 1

25r 0.0000000e+00 2.08e+02 7.82e+01 0.8 7.90e-02 2.8 1.00e+00 1.00e+00f 1

26r 0.0000000e+00 2.93e+02 1.41e+02 0.8 9.61e-01 2.3 2.45e-01 2.35e-01f 1

27r 0.0000000e+00 2.70e+02 7.26e+02 0.8 8.43e-01 1.8 3.36e-01 6.18e-02f 1

28r 0.0000000e+00 2.69e+02 7.21e+02 0.8 5.66e+02 - 1.20e-02 4.81e-03f 2

29r 0.0000000e+00 4.15e+02 6.03e+01 0.8 1.17e-01 1.4 1.00e+00 1.00e+00f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

30r 0.0000000e+00 8.56e+02 2.58e+02 0.8 7.00e+01 - 9.49e-01 4.42e-01f 2

31r 0.0000000e+00 6.84e+02 2.86e+02 0.8 2.71e+00 0.9 1.79e-01 2.01e-01h 1

32r 0.0000000e+00 5.92e+02 1.69e+02 0.8 2.88e+01 - 1.34e-01 3.24e-01f 1

33r 0.0000000e+00 4.89e+02 1.45e+02 0.8 1.92e+01 - 1.00e+00 1.00e+00f 1

34r 0.0000000e+00 7.71e+00 5.04e+01 0.8 1.11e+00 - 1.00e+00 1.00e+00h 1

35r 0.0000000e+00 8.63e+03 3.42e+01 -0.6 2.52e+01 - 6.33e-01 6.26e-01f 1

36r 0.0000000e+00 5.46e+03 5.26e+02 -0.6 1.02e+00 0.4 6.69e-01 3.70e-01f 1

37r 0.0000000e+00 2.30e+03 1.84e+02 -0.6 6.65e-01 0.8 6.29e-01 5.80e-01f 1

38r 0.0000000e+00 9.77e+02 7.18e+01 -0.6 1.85e+00 0.4 4.96e-01 6.05e-01f 1

39r 0.0000000e+00 7.39e+02 5.97e+01 -0.6 2.45e+00 -0.1 4.52e-01 4.94e-01h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

40r 0.0000000e+00 8.88e+02 1.40e+02 -0.6 7.33e+00 -0.6 6.79e-01 3.09e-01h 1

41r 0.0000000e+00 1.61e+01 1.29e+01 -0.6 3.68e-01 0.7 1.00e+00 1.00e+00h 1

42r 0.0000000e+00 6.47e+01 6.22e+00 -0.6 9.57e-01 0.3 1.00e+00 1.00e+00h 1

43r 0.0000000e+00 5.42e+02 5.88e+00 -0.6 3.02e+00 -0.2 1.00e+00 1.00e+00h 1

44r 0.0000000e+00 1.31e+03 5.88e+01 -0.6 9.54e+00 -0.7 5.38e-01 4.31e-01h 1

45r 0.0000000e+00 1.41e+03 2.73e+02 -0.6 1.19e+02 - 1.87e-01 1.21e-01h 1

46r 0.0000000e+00 1.08e+03 3.24e+02 -0.6 1.37e+02 - 6.36e-01 4.65e-01f 1

47r 0.0000000e+00 6.96e+02 2.77e+02 -0.6 8.41e+00 - 4.25e-01 3.72e-01h 1

48r 0.0000000e+00 1.45e+02 1.84e+02 -0.6 8.64e+00 - 5.45e-01 7.92e-01h 1

49r 0.0000000e+00 7.13e+01 3.91e+02 -0.6 2.50e+00 - 7.16e-01 5.13e-01h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

50r 0.0000000e+00 4.36e+00 1.14e+02 -0.6 2.79e+00 - 1.00e+00 1.00e+00f 1

51r 0.0000000e+00 6.03e-01 2.36e+01 -0.6 8.61e-01 - 1.00e+00 1.00e+00h 1

52r 0.0000000e+00 6.61e-01 4.55e+00 -0.6 2.56e-01 - 1.00e+00 1.00e+00h 1

53r 0.0000000e+00 1.10e+03 6.90e+01 -1.3 7.52e+01 - 9.02e-01 9.81e-01f 1

54r 0.0000000e+00 8.00e+00 8.01e-01 -1.3 2.37e+01 - 1.00e+00 1.00e+00h 1

55r 0.0000000e+00 1.78e+00 1.07e-01 -1.3 8.16e-01 - 1.00e+00 1.00e+00h 1

56r 0.0000000e+00 2.18e-01 5.40e-06 -1.3 3.90e-03 - 1.00e+00 1.00e+00h 1

57r 0.0000000e+00 1.15e+03 4.77e+01 -4.5 7.87e+01 - 7.94e-01 8.05e-01f 1

58r 0.0000000e+00 5.17e+02 1.43e+02 -4.5 2.20e+01 - 9.21e-01 5.56e-01h 1

59r 0.0000000e+00 2.84e+02 5.22e+02 -4.5 1.42e-01 -1.2 9.08e-01 4.51e-01h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

60r 0.0000000e+00 5.10e+01 1.24e+02 -4.5 2.35e-01 -1.6 9.14e-01 8.21e-01h 1

61r 0.0000000e+00 5.05e+01 4.54e+02 -4.5 4.49e+02 - 1.00e+00 2.18e-02h 1

62r 0.0000000e+00 1.39e+03 2.01e+02 -4.5 3.30e+00 - 1.00e+00 9.24e-01h 1

63r 0.0000000e+00 2.91e+02 7.48e+01 -4.5 1.78e-01 - 1.00e+00 7.97e-01h 1

64r 0.0000000e+00 4.07e+00 2.17e+01 -4.5 7.87e-02 - 1.00e+00 1.00e+00h 1

65r 0.0000000e+00 3.04e+00 2.05e+02 -4.5 5.95e-01 - 1.00e+00 2.50e-01h 3

66r 0.0000000e+00 2.27e+00 1.18e+02 -4.5 5.27e-01 - 1.00e+00 2.50e-01h 3

67r 0.0000000e+00 2.00e+00 6.21e+01 -4.5 3.35e-01 - 1.00e+00 5.00e-01h 2

68r 0.0000000e+00 9.09e-01 8.92e-02 -4.5 1.44e-01 - 1.00e+00 1.00e+00h 1

69r 0.0000000e+00 2.78e-01 2.22e-02 -4.5 6.01e-02 - 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

70r 0.0000000e+00 2.78e-01 9.38e-05 -4.5 1.31e-03 - 1.00e+00 1.00e+00h 1

71r 0.0000000e+00 5.15e+01 1.10e+01 -6.8 7.08e-01 - 9.31e-01 8.92e-01h 1

72r 0.0000000e+00 2.90e+01 4.50e+02 -6.8 1.50e-01 - 7.13e-01 4.39e-01h 1

73r 0.0000000e+00 7.89e+00 1.01e+02 -6.8 8.85e-02 - 8.77e-01 7.65e-01h 1

74r 0.0000000e+00 2.97e+00 1.42e+02 -6.8 9.08e-02 - 1.00e+00 7.58e-01h 1

75r 0.0000000e+00 8.82e-01 4.89e+01 -6.8 1.11e-01 - 8.59e-01 1.00e+00h 1

76r 0.0000000e+00 7.58e-01 1.53e-01 -6.8 1.32e-01 - 1.00e+00 1.00e+00h 1

77r 0.0000000e+00 2.82e-01 2.05e-01 -6.8 7.96e-02 - 1.00e+00 1.00e+00h 1

78r 0.0000000e+00 2.82e-01 6.98e+01 -6.8 5.00e-01 - 2.24e-01 2.59e-01H 1

79r 0.0000000e+00 2.82e-01 2.94e+02 -6.8 1.59e-01 - 1.00e+00 1.67e-01f 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

80r 0.0000000e+00 2.81e-01 1.89e+02 -6.8 4.85e-01 - 8.32e-02 9.31e-02f 2

81r 0.0000000e+00 2.81e-01 5.14e+02 -6.8 7.87e-04 -2.1 4.98e-01 7.44e-01h 1

82r 0.0000000e+00 2.81e-01 9.19e+02 -6.8 2.22e-04 -2.6 1.00e+00 2.63e-01h 1

83r 0.0000000e+00 2.81e-01 1.65e-02 -6.8 9.95e-04 -3.1 1.00e+00 1.00e+00f 1

84r 0.0000000e+00 7.23e+00 1.63e-01 -6.8 4.06e-01 - 1.00e+00 1.00e+00h 1

85r 0.0000000e+00 2.87e-01 2.33e-04 -6.8 9.28e-03 - 1.00e+00 1.00e+00h 1

86r 0.0000000e+00 2.87e-01 1.97e+00 -6.8 5.56e-01 - 1.00e+00 1.22e-04h 14

87r 0.0000000e+00 2.87e-01 2.46e+00 -6.8 5.00e-01 - 1.00e+00 1.22e-04h 14

88r 0.0000000e+00 2.87e-01 2.58e+00 -6.8 4.78e-01 - 1.00e+00 1.22e-04h 14

89r 0.0000000e+00 2.87e-01 2.62e+00 -6.8 4.70e-01 - 1.00e+00 1.22e-04h 14

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

90r 0.0000000e+00 2.87e-01 2.64e+00 -6.8 4.67e-01 - 1.00e+00 1.22e-04h 14

91r 0.0000000e+00 2.87e-01 2.64e+00 -6.8 4.66e-01 - 1.00e+00 1.22e-04h 14

92r 0.0000000e+00 2.87e-01 2.64e+00 -6.8 4.65e-01 - 1.00e+00 1.22e-04h 14

93r 0.0000000e+00 2.87e-01 2.64e+00 -6.8 4.65e-01 - 1.00e+00 1.22e-04h 14

94r 0.0000000e+00 2.87e-01 2.64e+00 -6.8 4.65e-01 - 1.00e+00 1.22e-04h 14

95r 0.0000000e+00 2.87e-01 2.64e+00 -6.8 4.65e-01 - 1.00e+00 1.22e-04h 14

96r 0.0000000e+00 9.42e+00 1.88e-02 -6.8 4.65e-01 - 1.00e+00 1.00e+00w 1

97r 0.0000000e+00 2.93e-01 1.19e-06 -6.8 8.82e-04 - 1.00e+00 1.00e+00w 1

98r 0.0000000e+00 2.93e-01 5.78e-06 -6.8 2.07e-03 - 1.00e+00 1.00e+00w 1

99r 0.0000000e+00 2.93e-01 2.04e-11 -6.8 4.54e-06 - 1.00e+00 1.00e+00h 1

iter objective inf_pr inf_du lg(mu) ||d|| lg(rg) alpha_du alpha_pr ls

100r 0.0000000e+00 7.74e-01 4.78e+00 -9.0 2.09e-01 - 6.64e-01 6.37e-01h 1

101r 0.0000000e+00 8.46e+00 3.40e+01 -9.0 3.17e-01 - 9.10e-01 7.63e-01h 1

102r 0.0000000e+00 4.04e+00 2.19e+02 -9.0 2.21e-01 - 8.62e-01 6.33e-01h 1

103r 0.0000000e+00 7.03e+00 1.45e+00 -9.0 1.41e-01 - 1.00e+00 1.00e+00h 1

104r 0.0000000e+00 7.21e-01 5.48e-01 -9.0 9.46e-02 - 1.00e+00 1.00e+00h 1

105r 0.0000000e+00 2.97e-01 1.72e-02 -9.0 7.60e-02 - 1.00e+00 1.00e+00h 1

106r 0.0000000e+00 2.97e-01 6.61e-05 -9.0 2.35e-02 - 1.00e+00 1.00e+00h 1

107r 0.0000000e+00 2.97e-01 1.83e-06 -9.0 1.21e-03 - 1.00e+00 1.00e+00h 1

108r 0.0000000e+00 2.97e-01 3.43e-08 -9.0 2.97e-04 - 1.00e+00 1.00e+00h 1

Number of Iterations....: 108

(scaled) (unscaled)

Objective...............: 0.0000000000000000e+00 0.0000000000000000e+00

Dual infeasibility......: 3.0151134107357916e-07 3.0151134107357916e-07

Constraint violation....: 2.9731578903766509e-01 2.9731578903766509e-01

Complementarity.........: 9.0909090909099699e-10 9.0909090909099699e-10

Overall NLP error.......: 2.9731578903766509e-01 2.9731578903766509e-01

Number of objective function evaluations = 271

Number of objective gradient evaluations = 3

Number of equality constraint evaluations = 271

Number of inequality constraint evaluations = 0

Number of equality constraint Jacobian evaluations = 111

Number of inequality constraint Jacobian evaluations = 0

Number of Lagrangian Hessian evaluations = 109

Total CPU secs in IPOPT (w/o function evaluations) = 0.155

Total CPU secs in NLP function evaluations = 0.015

EXIT: Converged to a point of local infeasibility. Problem may be infeasible.

7 Analyze the results

If the IDAES UI package was installed with the idaes-pse installation or installed separately, you can run the flowsheet visualizer to see a full diagram of the full process that is generated and displayed on a browser window.

Otherwise, we can run the m.fs.report() method to see a full summary of the solved flowsheet. It is recommended to adjust the width of the output as much as possible for the cleanest display.

====================================================================================

Flowsheet : fs Time: 0.0

------------------------------------------------------------------------------------

Stream Table

Units s01 s02 s03 s04 s05 s06 s07 s08 s09 s10 s11 s12

Total Molar Flowrate Liq mole / second 0.30001 2.0000e-05 0.29609 4.7359e-12 0.22506 1.0000e-08 0.30007 8.0134e-09 8.0151e-09 1.0000e-08 0.30007 2.0077e-09

Total Molar Flowrate Vap mole / second 4.0000e-05 0.32002 0.32272 0.61696 0.075008 2.0137e-10 1.0000e-08 1.5056e-10 1.3399e-10 1.9913e-08 1.0000e-08 4.0429e-11

Total Mole Fraction ('Liq', 'benzene') dimensionless 3.3332e-05 0.50000 0.00012935 5.9851e-05 1.0000e-20 1.0000e-20 1.0000e-20 0.0016277 0.0017605 1.0000e-20 1.0000e-20 0.0038222

Total Mole Fraction ('Liq', 'toluene') dimensionless 0.99997 0.50000 0.99987 0.99994 1.0000 1.0000 1.0000 0.99837 0.99824 1.0000 1.0000 0.99618

Total Mole Fraction ('Vap', 'benzene') dimensionless 0.25000 3.1248e-05 5.2698e-06 6.4834e-05 1.0000e-20 1.0000e-20 1.0000e-20 0.00017956 0.00019422 1.0000e-20 1.0000e-20 0.00042167

Total Mole Fraction ('Vap', 'toluene') dimensionless 0.25000 3.1248e-05 0.012327 0.48630 1.0000 0.037785 0.037785 0.037723 0.037718 0.51680 0.51680 0.037640

Total Mole Fraction ('Vap', 'hydrogen') dimensionless 0.25000 0.93744 0.92592 0.48184 1.3527e-09 0.49388 0.49388 0.49395 0.49398 0.24801 0.24801 0.49387

Total Mole Fraction ('Vap', 'methane') dimensionless 0.25000 0.062496 0.061748 0.031794 1.2842e-09 0.46834 0.46834 0.46815 0.46810 0.23519 0.23519 0.46807

Temperature kelvin 303.20 303.20 300.45 600.00 664.03 325.00 325.00 325.00 325.00 375.00 375.00 325.00

Pressure pascal 3.5000e+05 3.5000e+05 3.5000e+05 3.5000e+05 3.5000e+05 3.5000e+05 3.5000e+05 3.5000e+05 3.5000e+05 1.5000e+05 1.5000e+05 3.5000e+05

====================================================================================

What is the total operating cost?

operating cost = $ 225939.23444372677

For this operating cost, what is the amount of benzene we are able to produce and what purity we are able to achieve? We can look at a specific unit models stream table with the same report() method.

====================================================================================

Unit : fs.F102 Time: 0.0

------------------------------------------------------------------------------------

Unit Performance

Variables:

Key : Value : Units : Fixed : Bounds

Heat Duty : 2575.4 : watt : False : (None, None)

Pressure Change : -2.0000e+05 : pascal : True : (None, None)

------------------------------------------------------------------------------------

Stream Table

Units Inlet Vapor Outlet Liquid Outlet

Total Molar Flowrate Liq mole / second 0.30007 - -

Total Molar Flowrate Vap mole / second 1.0000e-08 - -

Total Mole Fraction ('Liq', 'benzene') dimensionless 1.0000e-20 - -

Total Mole Fraction ('Liq', 'toluene') dimensionless 1.0000 - -

Total Mole Fraction ('Vap', 'benzene') dimensionless 1.0000e-20 - -

Total Mole Fraction ('Vap', 'toluene') dimensionless 0.037785 - -

Total Mole Fraction ('Vap', 'hydrogen') dimensionless 0.49388 - -

Total Mole Fraction ('Vap', 'methane') dimensionless 0.46834 - -

Temperature kelvin 325.00 - -

Pressure pascal 3.5000e+05 - -

flow_mol_phase Liq mole / second - 1.0000e-08 0.30007

flow_mol_phase Vap mole / second - 1.9913e-08 1.0000e-08

mole_frac_phase_comp ('Liq', 'benzene') dimensionless - 1.0000e-20 1.0000e-20

mole_frac_phase_comp ('Liq', 'toluene') dimensionless - 1.0000 1.0000

mole_frac_phase_comp ('Vap', 'benzene') dimensionless - 1.0000e-20 1.0000e-20

mole_frac_phase_comp ('Vap', 'toluene') dimensionless - 0.51680 0.51680

mole_frac_phase_comp ('Vap', 'hydrogen') dimensionless - 0.24801 0.24801

mole_frac_phase_comp ('Vap', 'methane') dimensionless - 0.23519 0.23519

temperature kelvin - 375.00 375.00

pressure pascal - 1.5000e+05 1.5000e+05

====================================================================================

benzene purity = 1.934999854274726e-20

Next, let’s look at how much benzene we are losing with the light gases out of F101. IDAES has tools for creating stream tables based on the Arcs and/or Ports in a flowsheet. Let us create and print a simple stream table showing the stream leaving the reactor and the vapor stream from F101.

Units Reactor Light Gases

Total Molar Flowrate Liq mole / second 0.22506 1.0000e-08

Total Molar Flowrate Vap mole / second 0.075008 2.0137e-10

Total Mole Fraction ('Liq', 'benzene') dimensionless 1.0000e-20 1.0000e-20

Total Mole Fraction ('Liq', 'toluene') dimensionless 1.0000 1.0000

Total Mole Fraction ('Vap', 'benzene') dimensionless 1.0000e-20 1.0000e-20

Total Mole Fraction ('Vap', 'toluene') dimensionless 1.0000 0.037785